| Name: | LZJ02 Semi-automatic spacer bending machine |

|---|---|

| Core Components: | PLC |

| Key selling points: | easy operation |

| Warranty: | 18 months |

| Delivery: | 10 workdays after deposit |

| Payment: | TT,LC |

Product Description

Main Features

1. It consists of incline table, bending system, measuring ruler gauges & stoppers, cutting & control system.

2. Incline table is a structure where spacer bars are bent and lean. Bending system is composed of bending tools, support rollers and pneumatic system. Measuring ruler gauges are used as guidelines for two stoppers moved to proper positions. Cutting system includes motorized cutting blade to cut spacer bar instantaneously.

3. The machine adopt PLC controller, can complete the whole procedure automatically after calculation and manually putting spacer into the machine.

4. The head of the cutter can be adjusted automatically. It can operates without changing the cutter aluminum spacer when the width of the spacer is bigger than 6mm.

5. Cutting the end automatically when the processing is done

6. Adjusting the bending speed automatically.

7. The machine feature easy operation, reliable positioning, steady running, large processing range and high efficiency.

Highlights

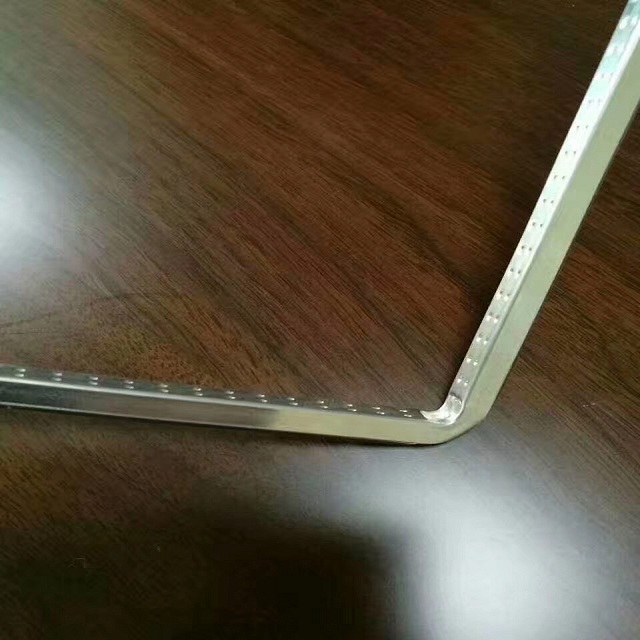

♥ Sophisticated bending tool and support rollers allow spacer bending corners in perfect shape and good looking. Corners are dimensionally stable and are non-distorted.

♥ Thanks to advanced cutting tool and technology, no burr or chip are found on cutting edges. It does not affect joint quality between spacer bars. This bending machine can also act as cutting machine in case necessary.

Technical Parameters

Power supply | 220V 50HZ |

Air pressure | 0.5~0.8Mpa |

Min spacer frame size | 280x280mm |

Max spacer frame size | 2000x2000mm |

Bending angle | 90° |

Width of alu spacer | 5.5~23.5mm |

Production tolerances | ±0.3mm |

Overall dimension | 3400x1600x2300mm |

Weight | 300KGS |

Our Products

LBW2500 Insulating Glass Production Line

This insulating glass production line is Automatic glass washing and combining line with panel pressing

Read MoreLBW1800 Insulated Glass Assembly Line IG Equipment

You are looking for insulated glass production machine? Find the perfect machine for insulating glass production here!

Read MoreJT02 Butyl Extruding Machine

The PLC Touch Screen Control Butyl Coating machine is used to coat both side of aluminum space bar for the assembly of insulated glass units. This machine applies an even amount of glue for high volume production of window glass.

Read MoreSDQ03 Silicone Sealant Sealing Machine for Insulating Glass

The Silicone Sealant Sealing Machine is used to apply sealant to form an Insulated Glass unit. This machine will allow the user to produce a very high volume of insulated units per shift. Choose good quality glass machine, click for quotation now.

Read MoreSTJ03 Pneumatic Two Component Sealant Extruder Machine

STJ03 Two Component Sealant Extruder Machine the main parts uses international famous brand. the HASCO motor is optional. Airtac pneumatic component is used. Easy operation, stable performance.

Read MoreRD-3000 Hot Melt Extruder Machine

This hot melt extruder machine is used for the second sealing of the insulating glass unit. Big sale for the machine now, click it for quotation now.

Read More