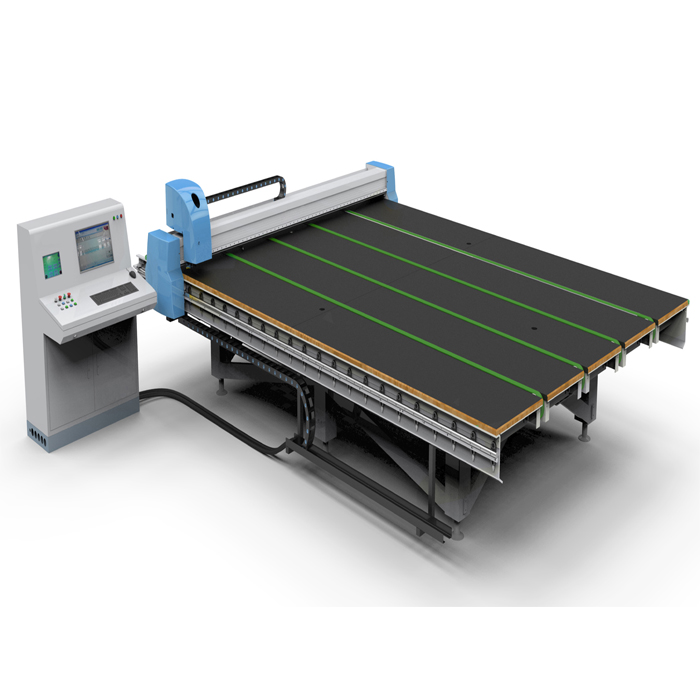

| Name: | SG-2621 CNC tempered glass cutting machine |

|---|---|

| guide rail: | Taiwan HINWIN |

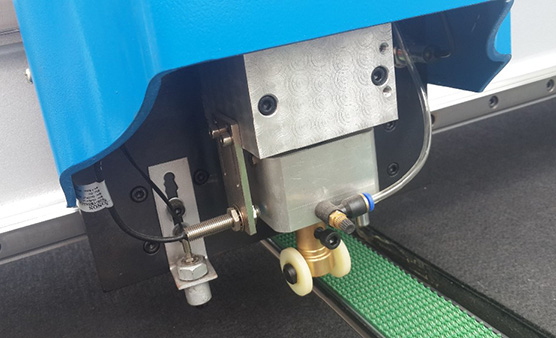

| Cutter wheel: | German Bohle |

| Motor: | Japan YASKAWA and other brands optional |

| Control card: | GALIL(USA) |

| Optimize Software: | OPTIMA |

| Frequency converter: | DELTA |

| Relay: | SCHNERDER |

| solenoid valve: | SMC JAPAN |

| A.C. contactor: | SCHNERDER |

Product Description

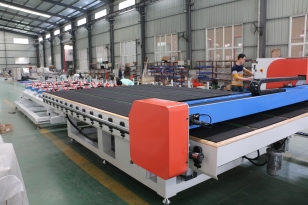

Jintai will show you the glass cutting machine series that is most popular with customers.Jintai has professional production workshops and great production technology. The Automatic glass cutting table we produce, in line with the national quality inspection standards, stable performance, good safety, and high reliability. It is also available in a wide range of types and specifications. Customers' diverse needs can be fully fulfilled.Jintai has established a complete service network to provide professional, standardized, and diversified services. The quality pre-sales and after-sales services can meet well the needs of customers.

Product

advantage

1. The table surface panel is high-density waterproof panel, roughness ≤±0.20mm/m (Imported material)

2. Taiwan HINWIN gear rack and linear guide rails. Highprecision.

3. German Bohle cutter wheels and holder, 360 degree free rotation.

4. DualJapan Yaskawa drive servo system, higher speed, excellent mechanical properties

5. Intelligent USA Galil motion controller, high-performance, Multiple motion patterns

6. Japan SMC Proportioning solenoid valve

7. PANASONIC laser sensor

8. Adopting Italian Optima optimization software, automatic layout optimization

The performance of OPTIMA OPTIMIZATION software used for the glass cutting table

-Optimization results can be imported in the office to do;

- Cutting programs can be created and edited manually.

- With a copy and move functions.

- You can manually edit the cutting sequence.

- XYZ mode can be used to quickly create cutting plan.

- Can be a variety of original pieces and small pieces while optimizing.

- Optimized layout no size limit.

- Optimization results rotate, mirror management.

- Cutting a small piece of the priority management to optimize.

- Priority management optimization original film.

- Original film library management.

- 20 kinds of efficient optimization algorithms.

- Graphics can be edited on the cutting.

- Label design and label printing (Label-WAY).

- Optimization results clearly printed report.

- Excel data file import.

- Low-E and laminated glass cutting management.

- Graphics library containing 350 parametric graphic, including all common

graphic types (Geo-Way).

- Two-dimensional CAD system with profiled scan processing functions

(Cad-Way).

- The digital signal is automatically converted to a numerical control

system from the graphical point forming.

- Software interface has a choice of languages, including Chinese

interface selectable.

- Tracking the latest international software development, providing real-time upgrade version, for customers to achieve the latest functional requirements.

Main Features

1. The head turn 360-degree rotation, upper and lower-cutting (which can be used to cut any straight line and a variety of shaped glass accurately

2. It adopt imported linear guide rail /racks and other high quality components

3. Sensor for glass presence verification avoid damaging to the cutting head.

4. use auto CAD software to make the cutting patterns design

5. Structure optima: The

equipment is made of welded steel pipes, body structure is designed and

analyzed completely, which reach the best situation. The sheet is made by 200mm

space to ensure that the table sets never deform.

Technical

Parameters

| Power | 3.2KW |

| Max cutting size | 2440x2000mm |

| Glass thickness | 2~19mm |

| Line parallelism | <0.15mm/m |

| Diagonal precision | <0.1mm/m |

Our Products

JTM-2621 CNC Automatic multifunctional Glass Cutting Machine

Explore reliable supplier of glass cutting machines for all kinds of glass. Visit the website to learn more. Get in touch to get more information.

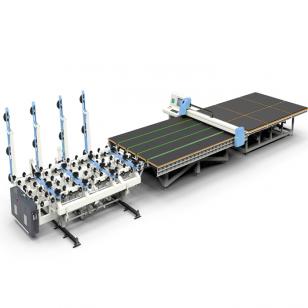

Read MoreJTL-CNC-4228 Automatic Glass Cutting Machine Line

The automatic glass cutting machine line comes with automatic glass loading system, automatic glass cutting table and glass breaking table and designed for cutting of all kinds glass, special glass types. High efficiency, High cutting precision.

Read MoreJT-1313 Multi Cutters Glass Cutting Machine

This multi cutters glass cutting machine can be used to cut all kinds of decoration shapes, such as small square, small round, small water drops, mirrors, etc. and it is well used in 1.5mm to 19mm thickness glass cutting, and it is very popular in glass p

Read MoreJTS-2621 Semi-Automatic Glass Cutting Machine

This multi cutting heads can be used to cut all kinds of decoration shapes,such as small square ,small round ,small water drops,etc.and it is well used in frosted glass cutting

Read MoreJTL-CNC-3826 Automatic Glass Cutting Machine Line

The automatic glass cutting machine line comes with automatic glass loading system, automatic glass cutting table and glass breaking table and designed for cutting of all kinds glass, special glass types. High efficiency, High cutting precision.

Read More